Turnkey Projects

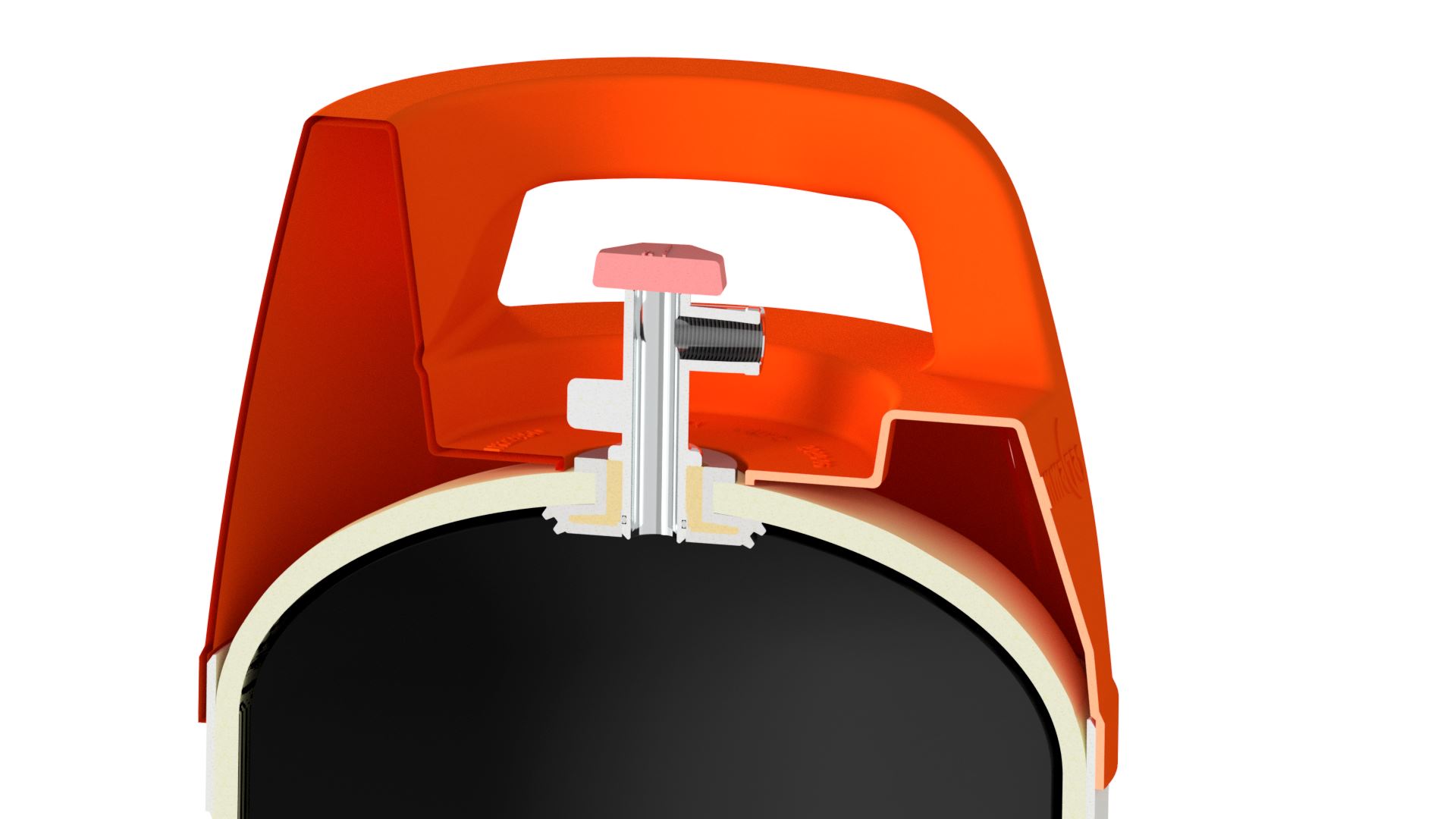

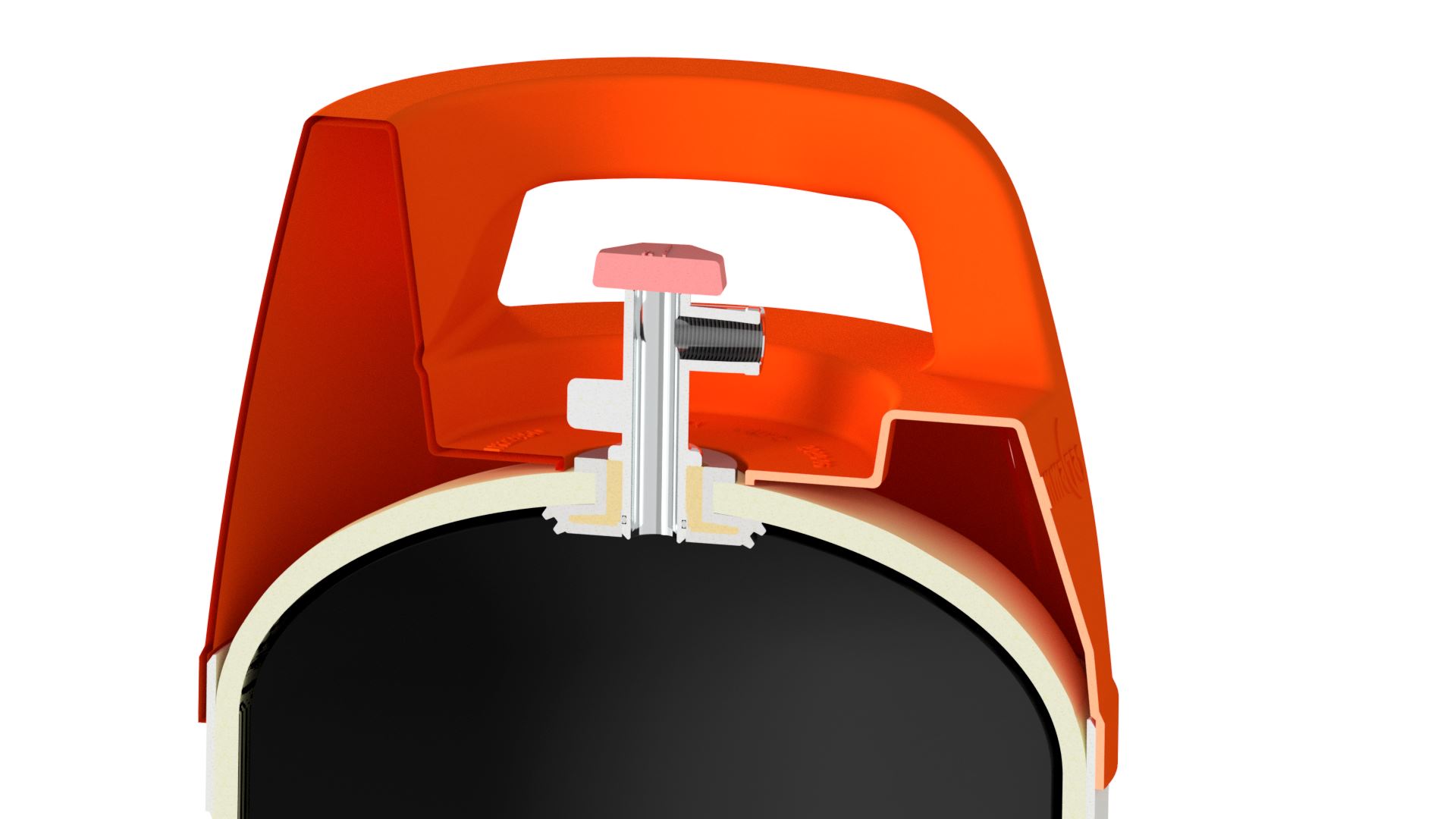

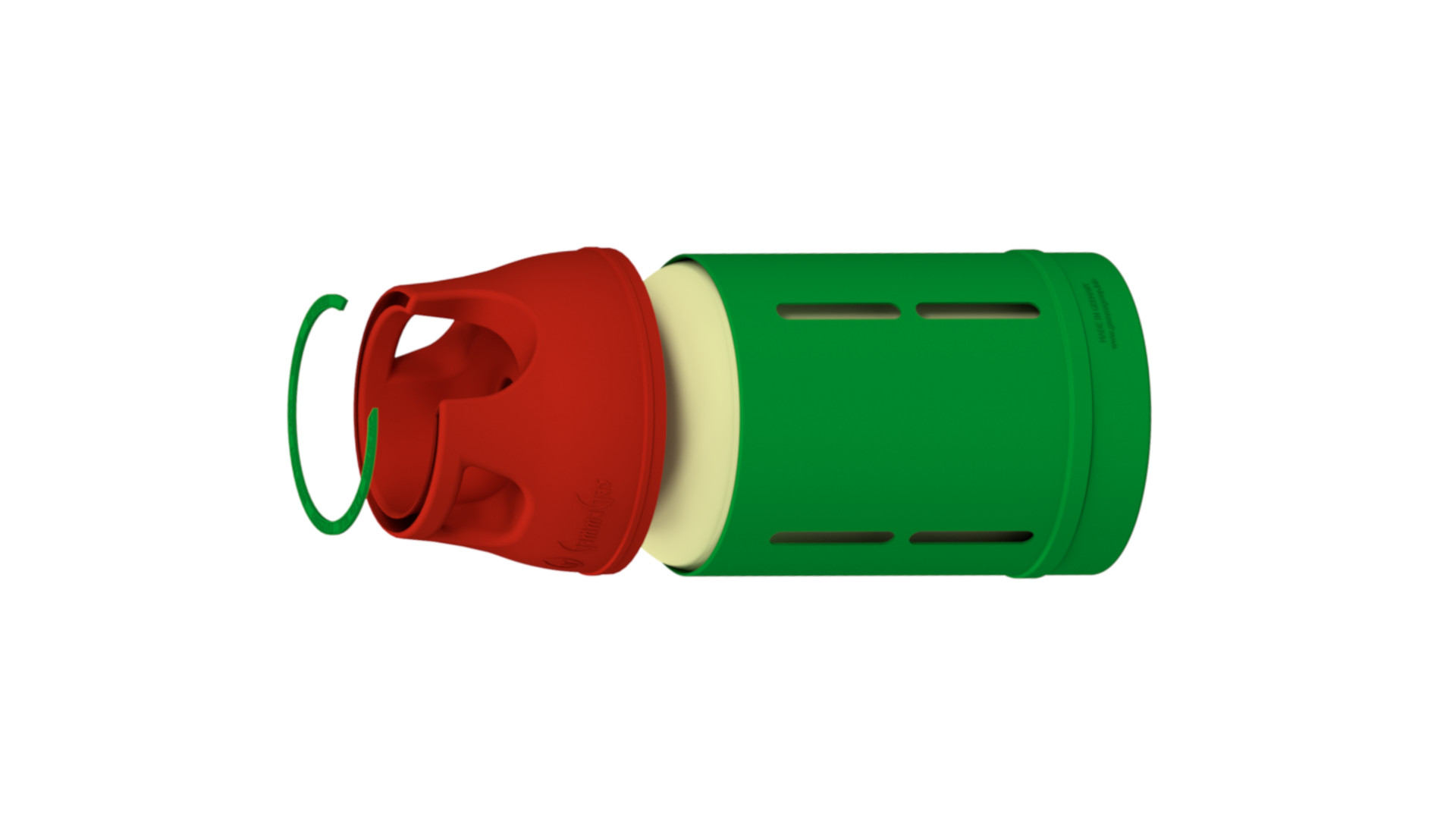

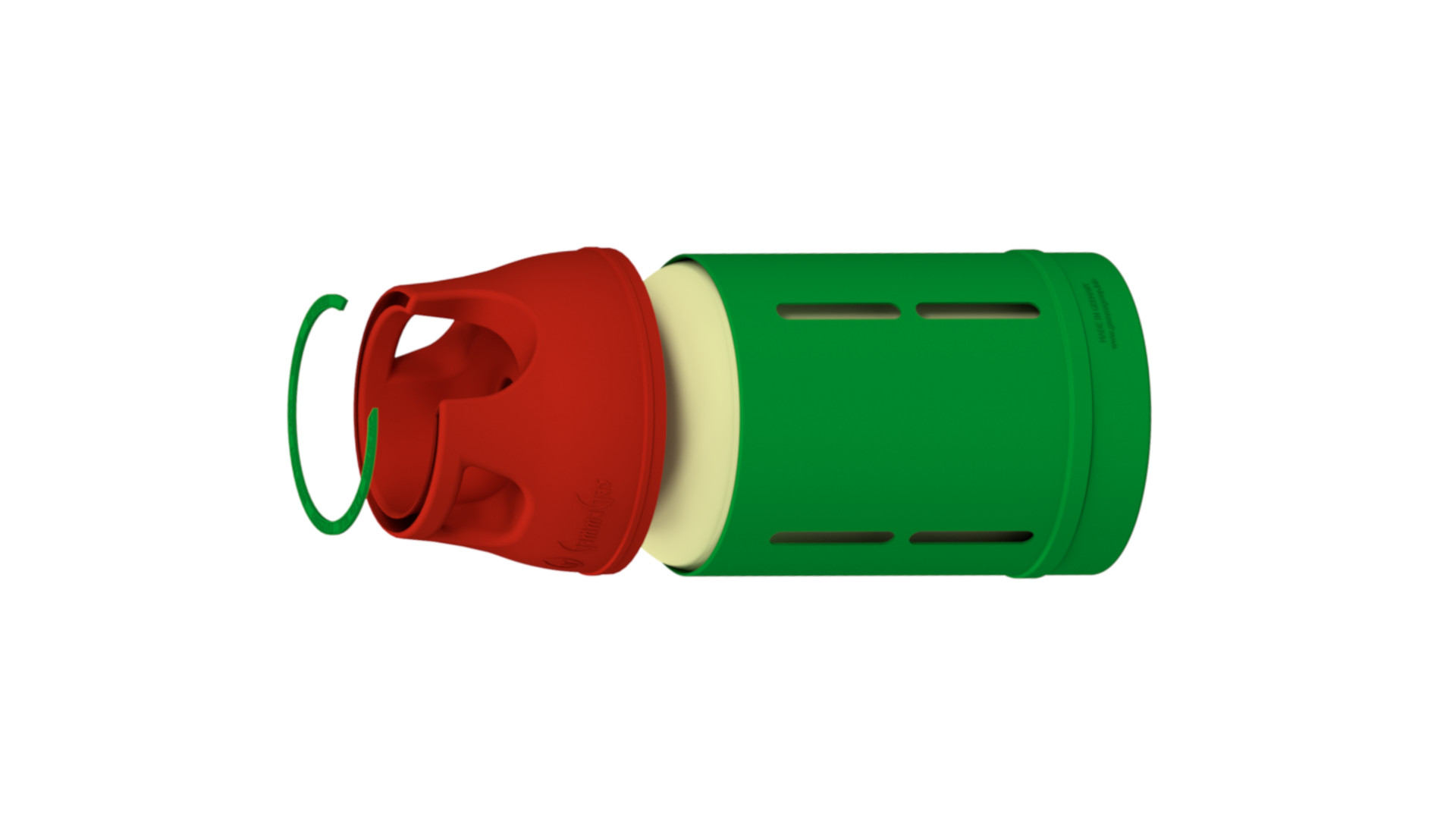

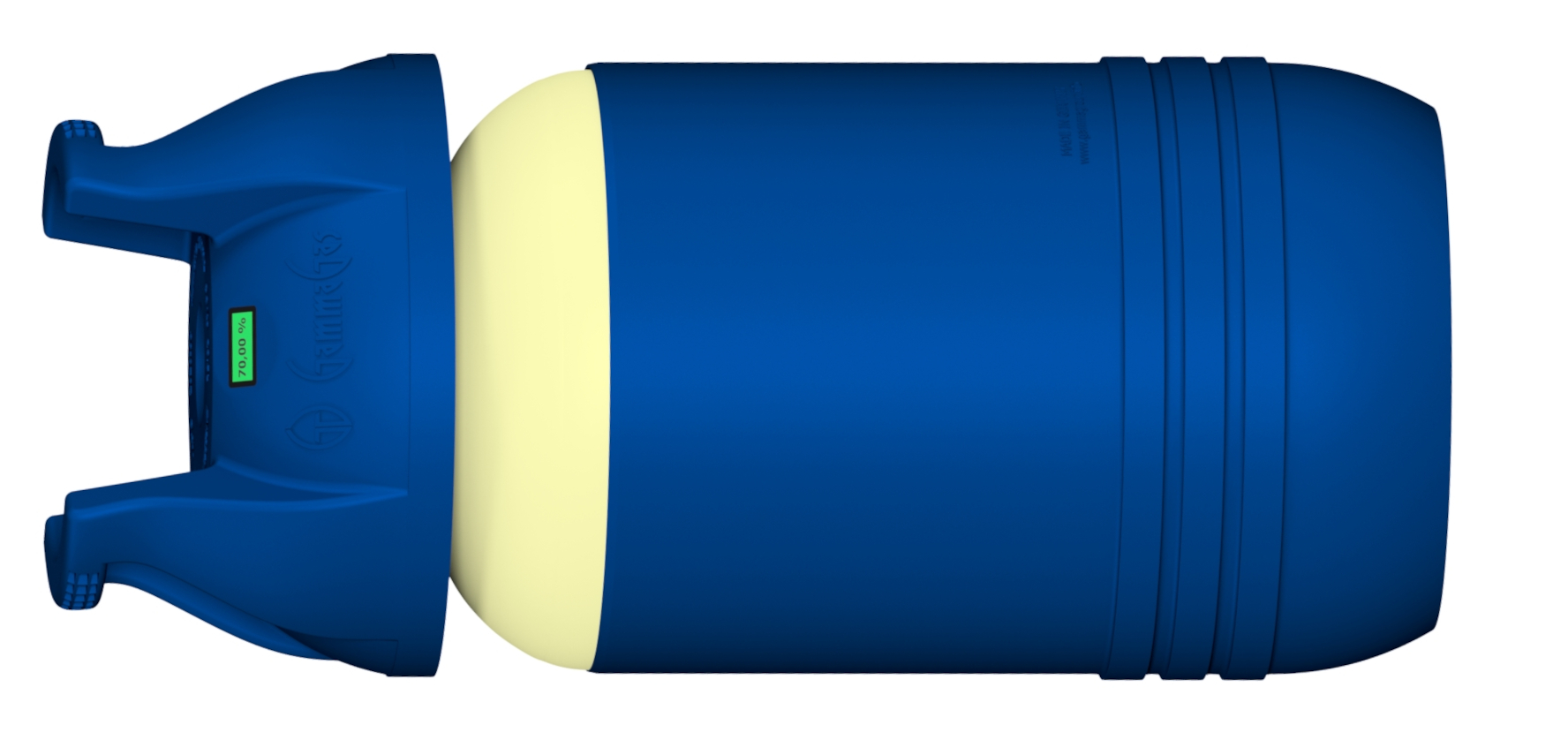

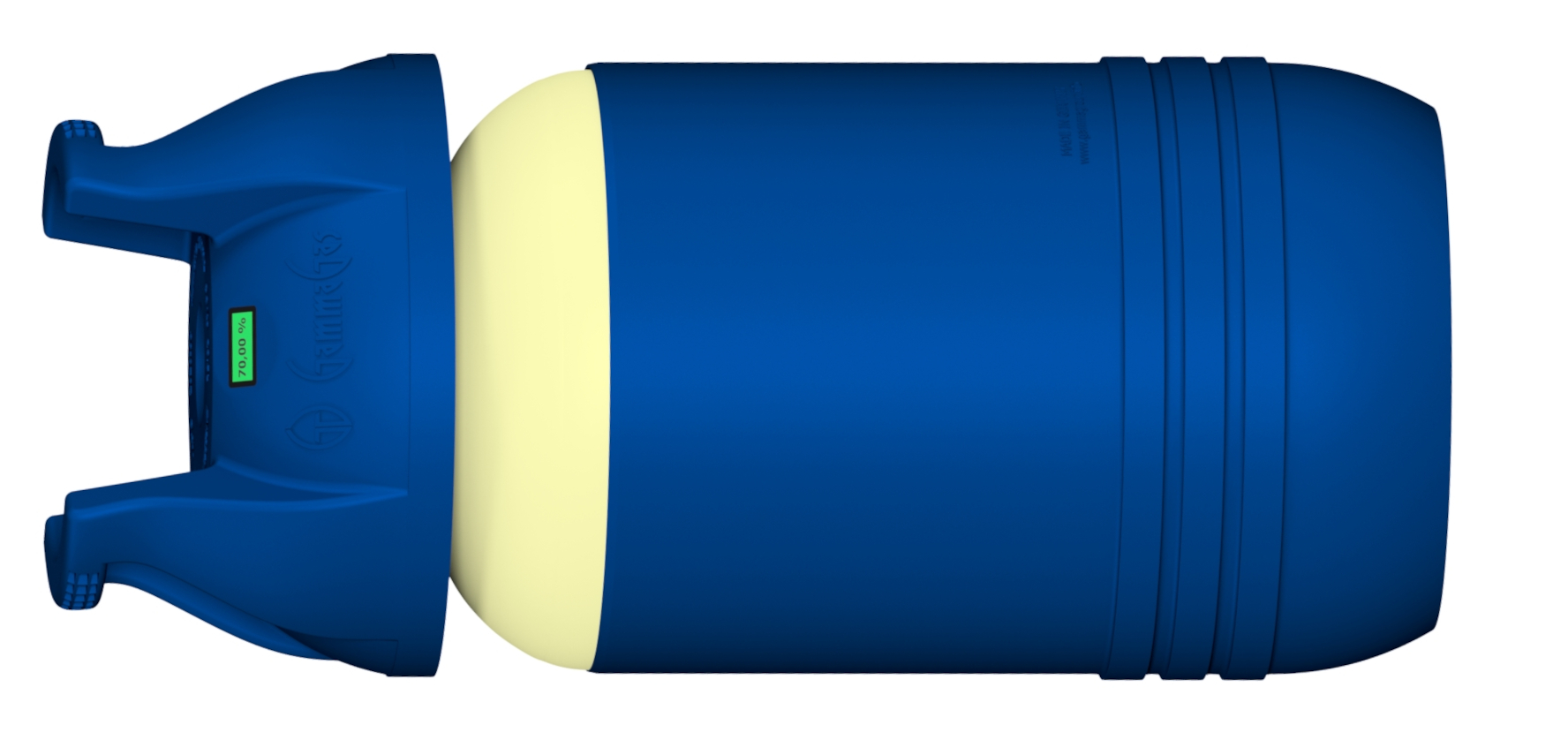

LPG COMPOSITE CYLINDERS

Starting with a HDPE blister to the winding unit of glass fiber and epoxy resin to outer packaging, Gammagroup and its partners will plan and establish the whole plant.

The expertise will be passed on to the customers and long-term contracts for after sales service and maintenance will be agreed upon.

All necessary documents such as TÜV and official certificates as well as all technical certificates will be created and passed on to the customers.

Because of high technical testing facilities, the customers are also able to create certificates for the sale of plastic gas bottles themselves.

Our LPG Composite Cylinders:

- are significantly lighter than steel containers

- are explosion-proof in case of fire and shock impact

- are stainless and UV resistant

- are optimized for storage and transport

- are provided with an electronical label for contactless identification,

- can be filled and maintained at every gas filling station

- have minimal operating costs

- are certified from TÜV Germany

- are highly customizable

Please see to our sales department for detailed technical data or a personalized quotation!

Want to know more about this product?

Download the data sheet

DownloadTechnical Data:

Design Norm: EN 12245 / ISO 11119-3

Tolerated temperature range: -40°C up to 65°C

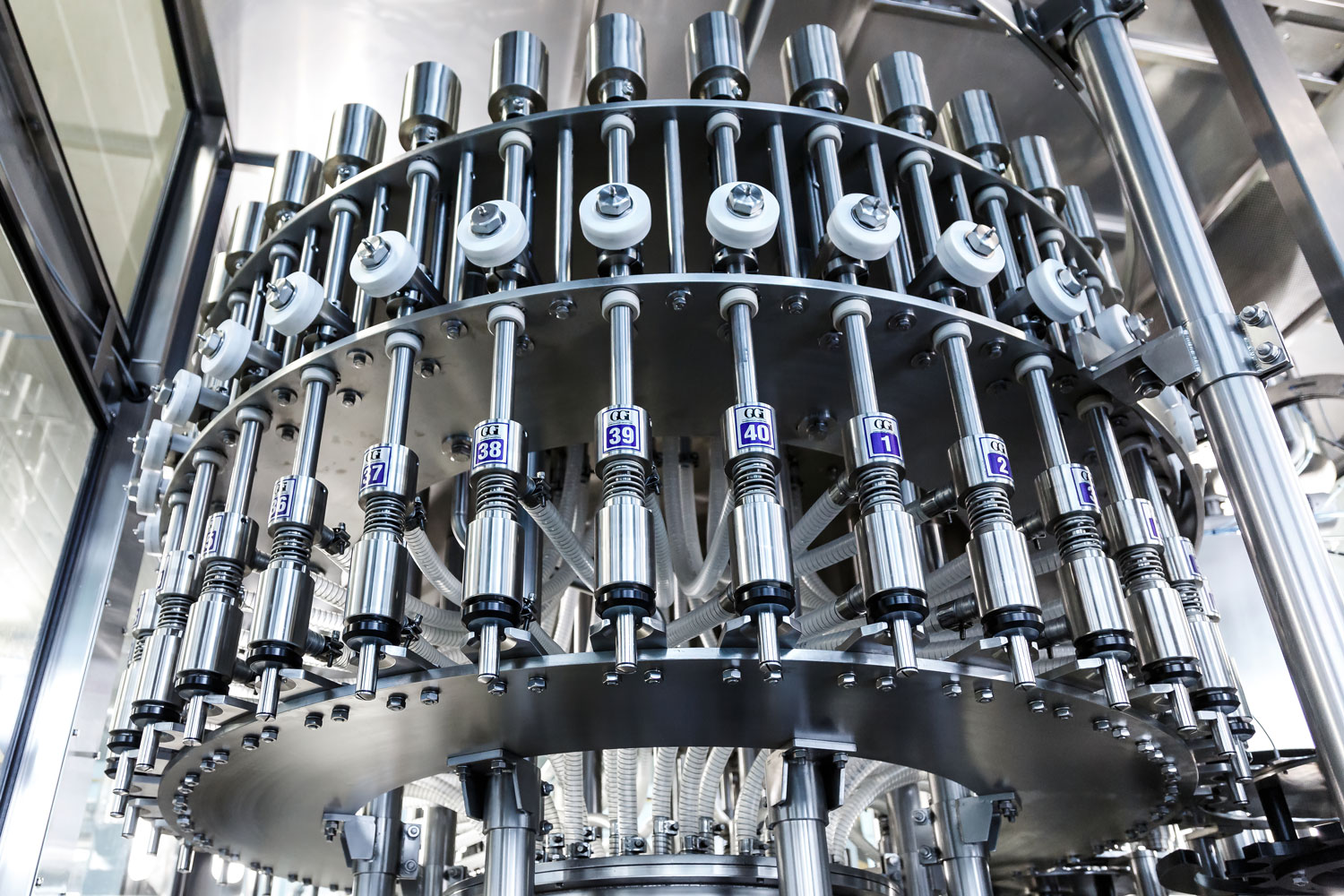

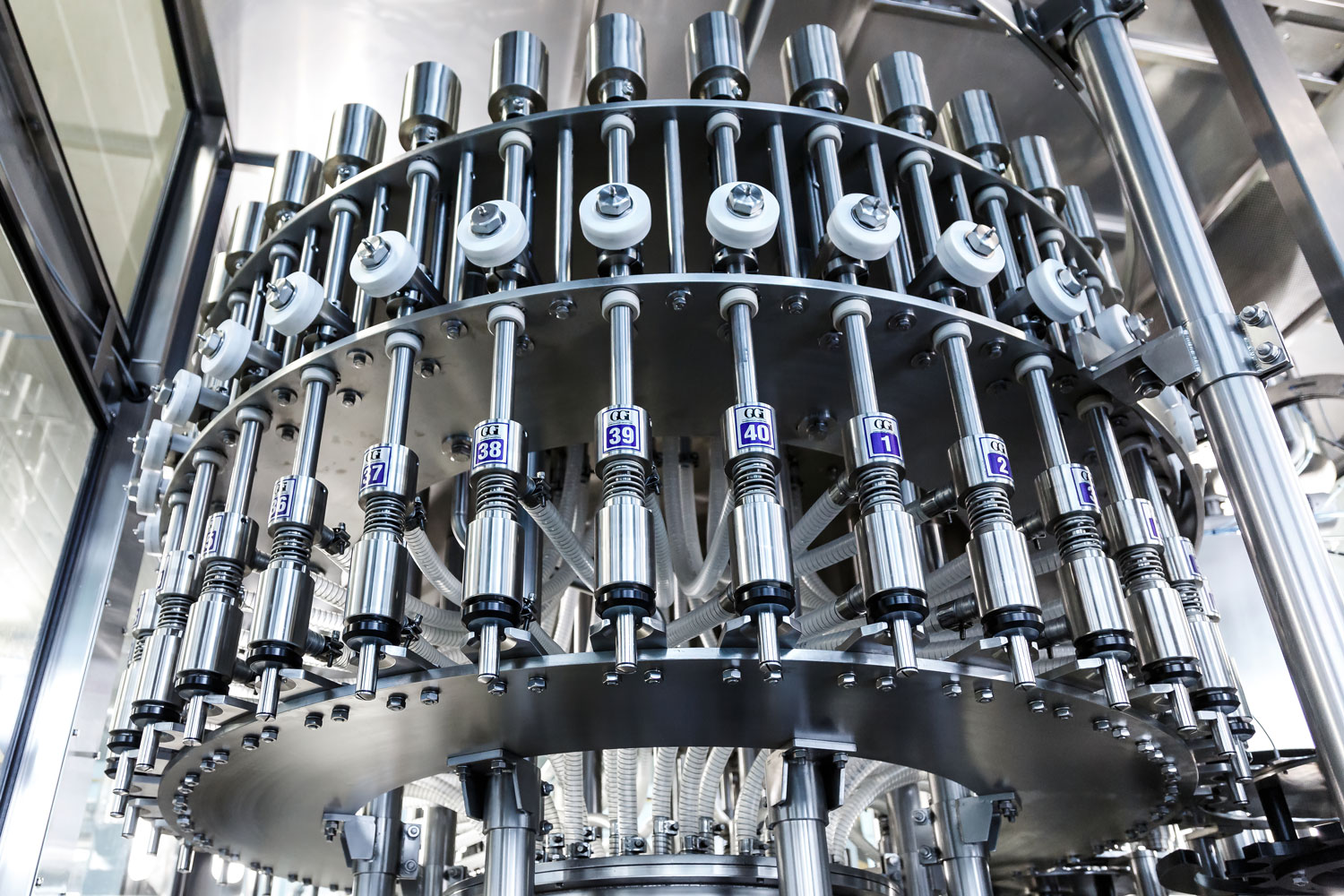

The production lines for PET bottles are designed to fill all kinds of liquids such as water, soft drinks, juices, and vegetable oil. The lines will be made to fulfill the needs of the customer and to correspond the demand of the market.

Currently there are facilities in South-America, the Middle-East and in Africa, that continuously produce with a capacity of 3.000 to 38.000 bottles per hour.

Gammagroup Industries takes over all assignments from project development to managing the facilities on site.

Furthermore, the company offers aftersales service contracts for 5 years and a delivery guarantee for spare parts for at least 10 years.

For more information, please contact the service team.

Please see to our sales department for detailed technical data or a personalized quotation!

As an alternative to aseptic cold filling, we offer hot filling for sensitive drinks in PET bottles.

Gammagroup produces PET bottles, which are suitable for elevated temperatures during the filling process.

Therefore, both the filling machine and the cooling tunnel will be equipped with this technology.

The customer will be submitted with the complete package to ensure a smooth production and can profit from the company’s long-term experience in this area.

Please see to our sales department for detailed technical data or a personalized quotation!

The conventional cold filling method is primarily used to produce water and carbon dioxide containing beverages in PET bottles. In addition, it is possible to fill bottles with sensitive products such as juices.

For this purpose, the cold sterilization chemical Velcorin® will be applied in minimal quantities by a pump.

This ensures, that the final product will have aseptic characteristics without the Velcorin® being detectable in the drink.

Please see to our sales department for detailed technical data or a personalized quotation!

* Velcorin® (Trademark: Lanxess AG)

The PET cans can be filled with any product.

PET cans can for example be filled with:

- Carbonated soft drinks

- Water and non carbonated drinks

- Juices (hot and cold filling)

- Beers

The fully automatic production lines are working with specially developed preforms and produce between 8.000 and 10.000 cans per hour. The speed is dependent of the can design and the product the cans will be filled with.

Please see to our sales department for detailed technical data or a personalized quotation!

To achieve an aseptic effect when it comes to the filling of fruit juices or other perishable drinks, hot filling is a well-known method. Due to heating of the product up to 70°C – 80°C, there is a slight loss of vitamins and taste.

However, Gammagroup can minimize the above-mentioned losses and provides the customer the complete concept.

Please see to our sales department for detailed technical data or a personalized quotation!

Cold filling can be used for all types of beverages.

For the cold filling of juice, the usage of the sterilization chemical Velcorin®, which is applied in a minimal quantity, is necessary. This leads to the Velcorin® not being detectable in the product.

In general, the filling of PET cans does not differentiate much from the filling of metal cans.

Therefore, it is possible to use the filling line of metal cans for PET cans as well.

Please see to our sales department for detailed technical data or a personalized quotation!

*Velcorin® (Trademark Lanxess AG).